Plasma Arc Weldin (PAW)

Plasma arc welding is basically a modification of the TIG process, the majority of the equipment being similar, but with modifications to the power source and torch design. PAW can be complementary to, or used as a substitute for, TIG welding, offering greater welding speed, less sensitivity to process variations and consequently better weld quality.

The welding capability range is much greater than TIG, particularly for low material thicknesses where micro-plasma units can operate as low as 0.1 amps, for the welding of very thin materials and high conductivity materials.

The PAW process has the ability to produce welds by the keyhole technique, this is used on closed square butts on material 1.5-10.0 mm thick. Full penetration in a single pass is achieved with considerably reduced distortion compared to more conventional welding processes.

PAW may require the use of a separately fed filler wire or may be used autogenously.

Method of operation

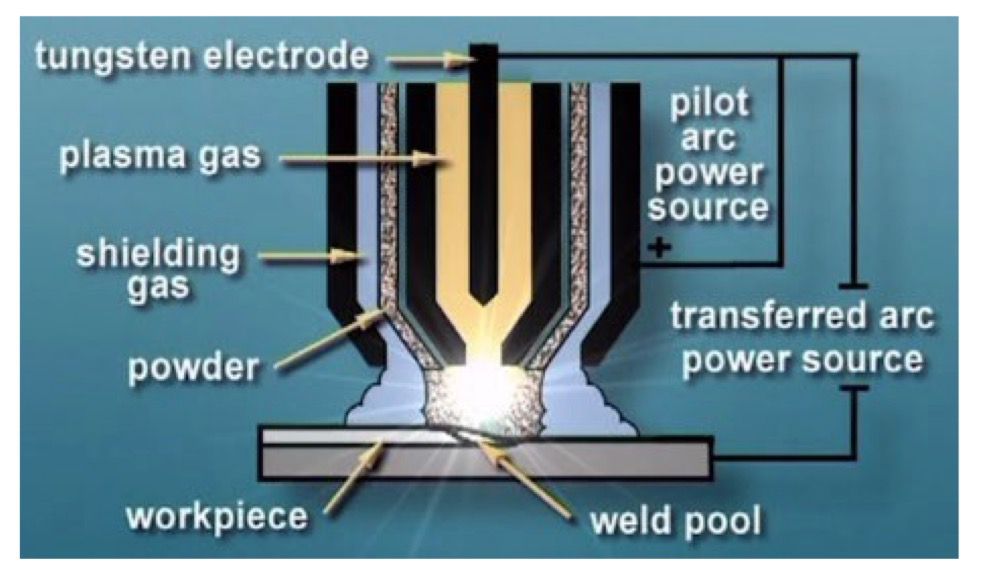

The welding torch consists of a non-consumable tungsten electrode set back into a constricted nozzle through which the plasma gas flows, this nozzle lies within another nozzle through which the shielding gas flows.

Gas is fed into the inner nozzle under low pressure and passes through the electric arc where it becomes ionized before being forced through the nozzle constriction. This increases the gas pressure and thus the temperature which is in the range of 10,000-17,000°C. This superheated ionized gas is referred to as plasma.

Power source and equipment

A conventional TIG power source, i.e. transformer/rectifier capable of operating in the range from 5 to 200 amps, may be used with an additional plug in plasma arc module, although purpose built units are available.

Shielding and plasma gases used are pure argon, helium or argon/helium/hydrogen mixtures dependent upon the material type being welded.

The electrode should be connected to the negative pole when DC is being used. When AC is used, a square wave form is recommended to give instant reversal of current

Methods of arc transfer

Two means of arc transfer are used in plasma arc welding, these being the transferred arc and non-transferred arc processes.

With the transferred arc process, the workpiece forms part of the circuit. The arc transfers from the electrode to the workpiece via the plasma gas; this results in additional heat output. The combined temperature of both arc and plasma is in the region of 17,000°C.

With the non-transferred arc process, the arc is initiated between the electrode and the constricting nozzle within the torch and only plasma gas (no arc) exits the nozzle; the work does not form part of the circuit. The plasma temperature is in the range of 10,000°C.